Basic Info.

Product Description

Product Description

Waterproof material Polypropylene/Polyester Short Fiber Needle Punched Nonwoven Geotextile Fabric,for Landfill/Dam/Water Tank/Artificial Lake/Aquatics/Road Construction,Good Price/Composite Geotextile/Composite Geomembrane/Geocomposite

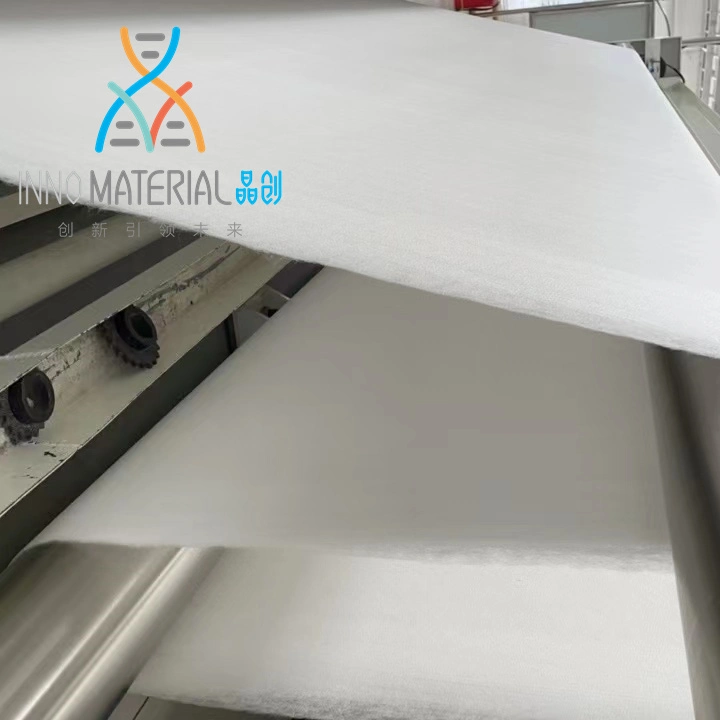

1)short fiber needle punched nonwoven geotextile fabric is made of polypropylene or polyester.

Its production process include fluffing,comb,mix,laying then needle punched.

2)Specification:

100GSM - 1500GSM

3)Raw Material: PP or Polyester

4)Properties:

Good flexibility, permeability, filtration, separation and easy for construction

5)Usage:

Nonwoven geotextile used in the area of highway, railway, dam,filtration of reinforcement for land ,

separation,drainage and protection.

6)Size of Package:

width 2-8m,length 50-100m (or at request).

7)Regular sizes for export:

100g/M2,150g/M2,200g/M2,250g/M2,300g/M2,350g/M2,400g/M2,450g/M2,500g/M2,600g/M2,800g

800g/M2,1000g/M2,

4m*50M Per Roll & 4M*100M Per Roll,or as required.

8)Delivery time:within 10-20 days after receiving the advance payment

9)Small pieces of Sample is available

- Features:

- Applications:

- Technical Data: Polypropylene

| Specification | unit | 100g | 200g | 300g | 400g | 500g | 600g | 700g | ||

| unit weight variation | % | ± 6 | ||||||||

| Grab strength | MD | N | ≥450 | ≥900 | ≥1200 | ≥1600 | ≥2000 | ≥2400 | ≥3200 | |

| TD | ≥450 | ≥900 | ≥1200 | ≥1600 | ≥2000 | ≥2400 | ≥3200 | |||

Trapezoidal tear strength | MD | N | ≥170 | ≥350 | ≥420 | ≥500 | ≥580 | ≥660 | ≥900 | |

| TD | ||||||||||

| ≥170 | ≥350 | ≥420 | ≥500 | ≥580 | ≥660 | ≥900 | ||||

| CBR mullen brust strength | kN | ≥1.3 | ≥2.5 | ≥3.5 | ≥4.3 | ≥5.5 | ≥6.5 | ≥9.0 | ||

| breaking strength | MD | kN/m | ≥5.0 | ≥11 | ≥16 | ≥22 | ≥28 | ≥35 | ≥48 | |

| TD | ≥5.0 | ≥11 | ≥16 | ≥22 | ≥28 | ≥35 | ≥48 | |||

| Elongation at break | MD | % | 40~70 | 50~80 | 70±20 | |||||

| TD | ||||||||||

| puncture resistance | N | ≥210 | ≥430 | ≥650 | ≥900 | ≥1200 | ≥1500 | ≥2500 | ||

Technical Data: Polyester

POLYSTER SHORT FIBER NEEDLE PUNCHED GEOTEXTILE

- Product Introduction:

- Features:

- Reducing soil and water loss effectively with feature of excellent water and air permeability.

- Excellent drainage property.

- Applying geotextile to improve tensile strength and non-deformability of soil, enhance the stability of building structure and reinforce the soil.

- Effectively diffuse, transfer or decompose the concentrated stress to prevent the soil from being damaged by external force.

- Prevent the mixture among underwater sand, soil body and concrete.

- The mesh is not easily blocked.

- High water permeability.

- Easy to construct, light weighted, convenient to use.

- Applications:

- Technical Data:

| Material: Polyster short fiber Needle punched Geotextile | ||||||||||

| Specification | Values | Remark | ||||||||

| Weight (g/m2) | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 800 | |

| Thickness (mm) | 0.8 | 1.2 | 1.7 | 2.4 | 3.0 | 3.6 | 4.10 | 4.50 | 5.0 | |

| Breaking Strength (≥KN/m) | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | MD&CD |

| Elongation at Break (%) | 25 to 100 | MD&CD | ||||||||

| CBR Bursting Strength (≥KN) | 0.6 | 1.0 | 1.4 | 1.8 | 2.5 | 3.2 | 4.0 | 5.5 | 7.0 | |

| Sieve Size [O95 O95] (mm) | 0.07 to 0.20 | |||||||||

| Vertical Permeability (cm/s) | Kv x (10-1 to 10-3); Kv = (1.0-9.9) | |||||||||

| Tear Strength (≥KN) | 0.10 | 0.15 | 0.20 | 0.25 | 0.40 | 0.50 | 0.65 | 0.80 | 1.00 | MD&CD |

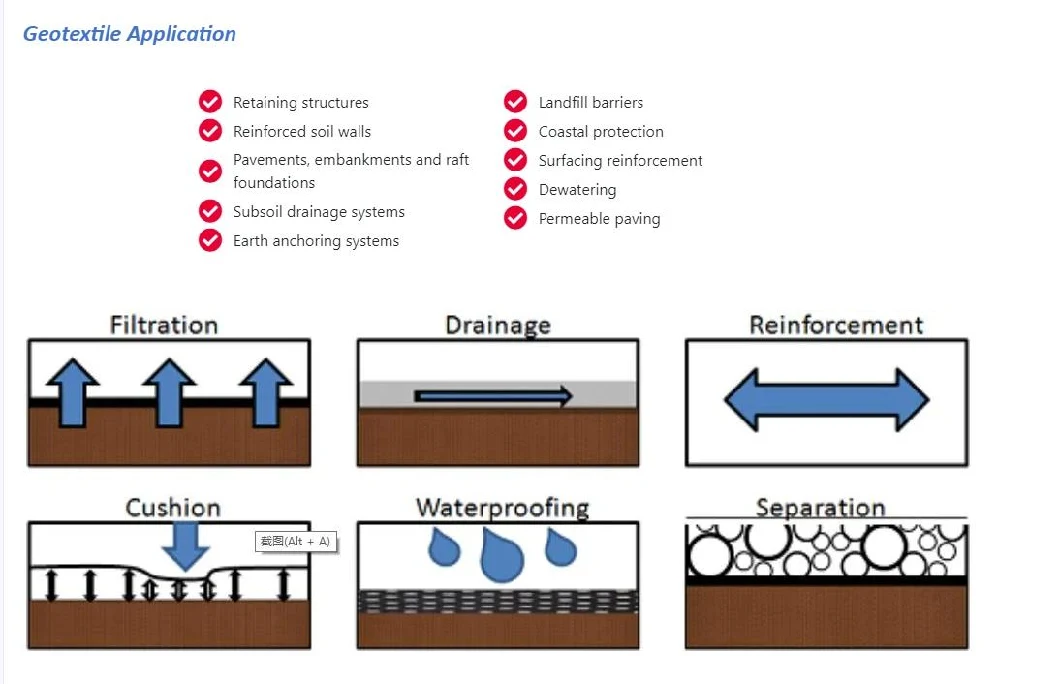

1.Separation

The separation function of geotextile is majorly used in the construction of roads. Geotextile prevents the intermixing of two adjacent soils. For example, by separating fine subgrade soil from the aggregates of the base course, the geotextile preserves the drainage and the strength characteristics of the aggregate material.

Some of the applicable areas are:

- Between subgrade and stone base in unpaved and paved roads and airfields.

- Between subgrade in railroads.

- Between landfills and stone base courses.

- Between geomembranes and sand drainage layers.

The equilibrium of geotextile-to-soil system that allows for adequate liquid flow with limited soil loss across the plane of the geotextile.

Porosity and permeability are the major properties of geotextiles which involve infiltration action.

A common application illustrating the filtration function is the use of a geotextile in a pavement edge drain, as shown in the figure above.

3.Reinforcement

Introduction of geotextile in the soil increases the tensile strength of the soil the same amount steel does in concrete. The strength gain in soil due to the introduction of geotextile is by the following 3 mechanisms :

- Lateral restraint through interfacial friction between geotextile and soil/aggregate.

- Forcing the potential bearing surface failure plane to develop an alternate higher shear strength surface.

- Membrane type of support of the wheel loads.

A layer of non-woven geotextile is impregnated in between existing and new asphalt layers. The geotextile absorbs asphalt to become a waterproofing membrane minimising vertical flow of water into the pavement structure.

Application

1. Road Work

Geotextiles are widely used in the construction of the road. It reinforces the soil by adding tensile strength to it. It is used as a rapid de-watering layer in the roadbed, the geotextiles need to preserve its permeability without losing its separating functions.

2. Railway Works

The woven fabrics or the non-woven ones are used to separate the soil from the sub-soil without impeding the groundwater circulation where the ground is unstable. Enveloping individual layers with fabric prevents the material from wandering off sideways due to shocks and vibrations from running trains.

3. Agriculture

It is used for mud control. For the improvement of muddy paths and trails those used by cattle or light traffic, nonwoven fabrics are used and are folded by overlapping to include the pipe or a mass of grit.

4. Drainage

The use of geotextiles to filter the soil and a more or less single size granular material to transport water is increasingly seen as a technically and commercially viable alternative to the conventional systems. Geotextiles perform the filtering mechanism for drainages in earth dams, in roads and highways, in reservoirs, behind retaining walls, deep drainage trenches, and agriculture.

5. River, Canals and Coastal Works

Geotextiles protect river banks from erosion due to currents or lapping. When used in conjunction with natural or artificial enrockments, they act as a filter.

Geotextile Installations Instructions

How to install geotextile fabric

Let us show you how easy the installation is and provide a few useful tips along the way. In our example,

Step 1 - Prep the road surface

First, you will need to excavate the roadway to the desired elevation. Then fully compact your subgrade, making sure you have removed all air and tightened the soil completely.

Step 2 - Unroll the reinforcement geotextile fabric

Roll the geotextile fabric on the compacted subgrade, making sure it's free of wrinkles and folds. Overlap your fabric as directed by the engineer. Cherokee can pre-sew the fabric for you if a stitch seam is required. Contact your Cherokee representative to get pricing on factory seamed rolls in a wider widths.

Step 3 - Sew the geotextile fabric

This job required the fabric to be stitched on the job site. The fabric needs to be seamed with a dual thread lock stitch to prevent it from unthreading. We have equipment available for purchase or rental to do the stitching on the job. At the engineers discretion you can choose a prayer seam, j-seam, or butterfly seam. In this example we will be using a j-seam. We recommend doing two stitches on each seam to prevent any failure during installation.

Step 4 - Apply Aggregate

Place your aggregate to the specified thickness, ensuring that no equipment drives directly on the engineered fill. Make sure the fill has reached full compaction before the final step.

Step 5 - Lay Asphalt

Now that you have placed your subbase you are ready for your pavement layer (or layers depending on the project type).

Packages and Shipment

Nonwoven Geotextile is packed in the woven bags or follow your demand.

Keep it away from moisture and fire!!!