Basic Info.

Product Description

POLYSTER FILAMENT SPUNBOND NEEDLE PUNCHED GEOTEXTILE

- Product Introduction:

- Features:

- Reducing soil and water loss effectively with feature of excellent water and air permeability.

- Excellent drainage property.

- Applying geotextile to improve tensile strength and non-deformability of soil, enhance the stability of building structure and reinforce the soil.

- Effectively diffuse, transfer or decompose the concentrated stress to prevent the soil from being damaged by external force.

- Prevent the mixture among underwater sand, soil body and concrete.

- The mesh is not easily blocked.

- High water permeability.

- Easy to construct, light weighted, convenient to use.

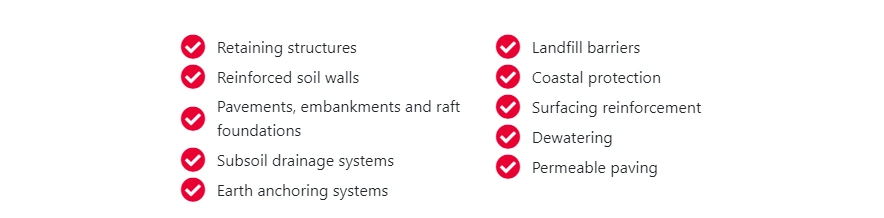

- Applications:

Our advantage:

| Specification | Values | ||||||||||

| Weight (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

| Weight variation (%) | ±4% | ||||||||||

| Thickness (mm) | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.4 | 4.2 | 5.5 |

| Width (m) | 1 to 6m (5.9m for container transportation) | ||||||||||

| Width deviation (%) | ±0.5% | ||||||||||

| Breaking Strength (≥KN/m) | 4.5 | 7.5 | 10.5 | 12.5 | 15 | 17 | 20 | 23 | 25 | 30 | 40 |

| Elongation at Break (%) | 40% to 80% | ||||||||||

| CBR Bursting Strength (≥KN/m) | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 6.4 | 7.9 |

| Sieve Size (mm) | 0.07 to 0.20 | ||||||||||

| Vertical Permeability Coefficient (cm/s) | Kv x (10-1 to 10-3); Kv = (1.0-9.9) | ||||||||||

| Tear Strength (≥KN/m) | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.50 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 |

Geotextile Application

Geotextile Installations Instructions

Geotextile Installations Instructions How to install geotextile fabric

Let us show you how easy the installation is and provide a few useful tips along the way. In our example,

Step 1 - Prep the road surface

First, you will need to excavate the roadway to the desired elevation. Then fully compact your subgrade, making sure you have removed all air and tightened the soil completely.

Step 2 - Unroll the reinforcement geotextile fabric

Roll the geotextile fabric on the compacted subgrade, making sure it's free of wrinkles and folds. Overlap your fabric as directed by the engineer. Cherokee can pre-sew the fabric for you if a stitch seam is required. Contact your Cherokee representative to get pricing on factory seamed rolls in a wider widths.

Step 3 - Sew the geotextile fabric

This job required the fabric to be stitched on the job site. The fabric needs to be seamed with a dual thread lock stitch to prevent it from unthreading. We have equipment available for purchase or rental to do the stitching on the job. At the engineers discretion you can choose a prayer seam, j-seam, or butterfly seam. In this example we will be using a j-seam. We recommend doing two stitches on each seam to prevent any failure during installation.

Step 4 - Apply Aggregate

Place your aggregate to the specified thickness, ensuring that no equipment drives directly on the engineered fill. Make sure the fill has reached full compaction before the final step.

Step 5 - Lay Asphalt

Now that you have placed your subbase you are ready for your pavement layer (or layers depending on the project type).

Packages and Shipment

Nonwoven Geotextile is packed in the woven bags or follow your demand.

Keep it away from moisture and fire!!!

Company Information

Name:

Shandong innovative material technology Co.,Ltd

Add:

NO.6399 East tianqu road dezhou city shandong province

Enterprise Culture:

Takes R&D as center, innovation as driving force, market as orientation, and talents as foundation.

Honor and certificate:

Shandong Famous Brand

Certificate of Inspection of Quality:CRCC Certification

Enterprise of Abiding by Strictly Contract and Being Trustworthy

ISO9001:2008 Quality Management System Certification; National Industrial Production License.

RELATED PRODUCTS

We are online 24 Hours Pls feel free to contact us if any requirement .